A little machine will save Parkway Products big money in labor, production time and material costs.

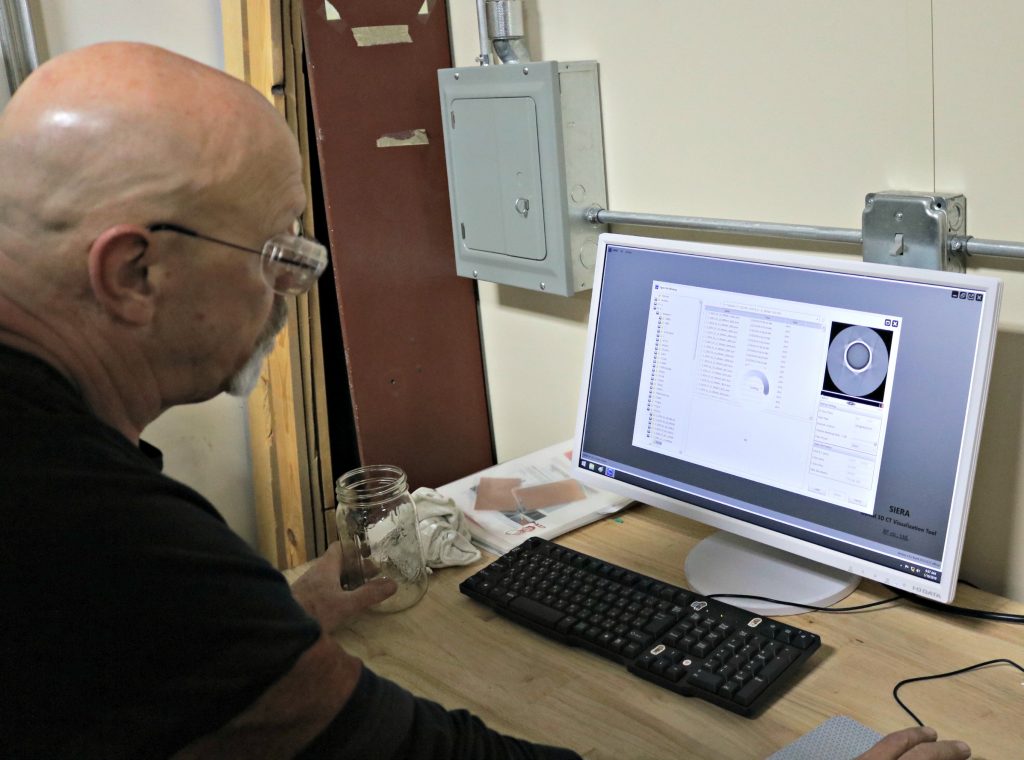

At the end of 2018, Parkway’s Littlestar Technology Center added a CT scanner to its growing number of machines that are used to perfect quality. The machine allows operators to test parts that have been injection molded and get immediate confirmation that the parts formed properly, without density gradients, contaminents or metal.

“What edge does this give us over other injection molders that don’t have a CT scanner? For the types of parts we do, it’s everything,” Carey Priest, Parkway application engineer said.

Parkway’s Littlestar division is one of the world leaders in producing parts and components from high-performance plastics such as Torlon, PEEK and Ultem. These are expensive polymers and the CT scanner will help Parkway remain competitive in the ever-price-sensitive plastics manufacturing industry.

“Let’s use Torlon as an example because it has to be baked,” Priest said. “After we mold a part with Torlon, it has to be put in a cure oven for 17 days. Once it’s out, it might be a couple of days before our machinists get to it. If you discover a problem then, you’ve lost three weeks of production time and you’ve got a lot of wasted product.”

Parkway had shortened that timeline by sending parts that have been injection molded to another company for scanning.

“They did a great job for us, but there’s a cost to each sheet of parts and the process took a few days, from when we sent them out to when we got them back. Now, we know immediately whether we have a problem and it creates a digital record that we can refer to if the customer has an issue.”

Parkway invested in the CT scanner is because its technology center continually looks for ways to tighten its processes and reduce waste. They looked at the data in 2018 and identified that the company could cut down on material costs in the injection molding department.

“This CT scanner is easy enough that almost everyone on the floor can run it. It’s small enough that it’s on a cart so it can be moved around. You put a part in, push a button, after a minute or two it gives you a digital readout. It’s like an MRI on your bones. You can see through the part. You can change orientations. You can roll it. You can see right away if you have density gradients, contaminants, metal. It’s going to pay for itself many, many times over.”

Companies come to Parkway because of our ability to prototype, machine, mold and mass-produce high-tolerance performance-polymer components. When it’s critical, they choose Parkway because we partner with our clients to find the best way to meet their goals. Our investment in a CT scanner is just one of the ways we deliver the best possible quality at the best possible price. Contact us to learn more about Parkway and our commitment to quality.